Enercat Wax Elimination Tool

We offer

The Nigerian Niger Delta crude oil, which is the mainstay of Nigerian economy, exhibits waxiness, with deposits in the range of 30-45 % (Adewusi 1997; Fasesan and Adewumi, 2003; Taiwo et al., 2009 and Oladiipo et al., 2009).

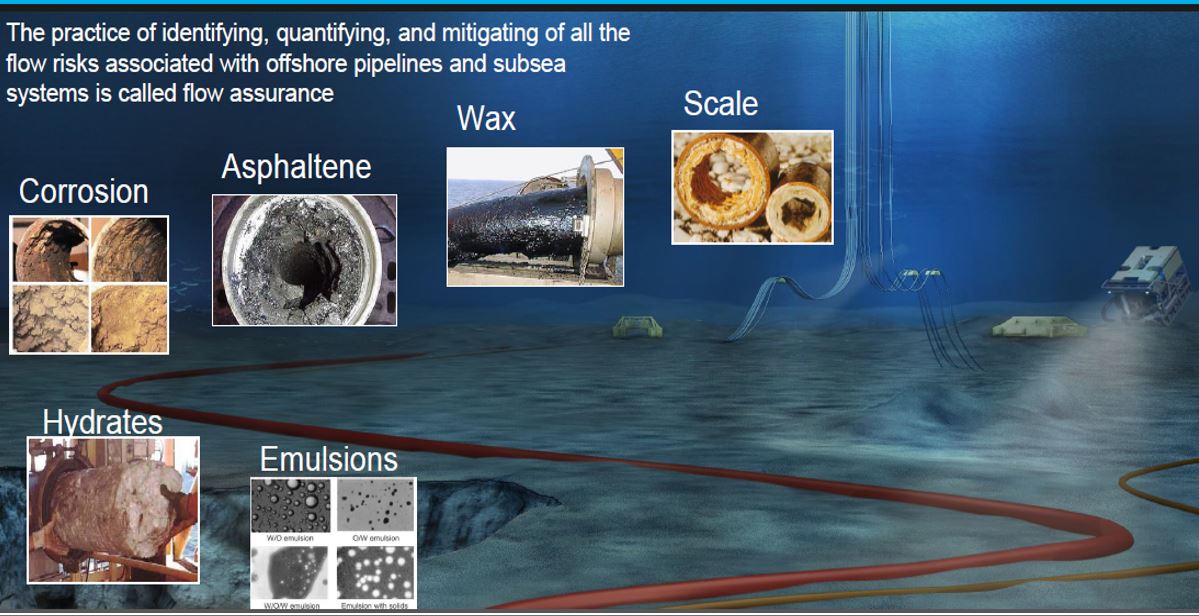

In fact, pipelines have been known to wax up beyond recovery in Nigeria. Production tubings have also been known to wax up, necessitating frequent wax cutting, using scrapers conveyed by wireline, which is an expensive practice Billions of dollars has been lost to its prevention and remediation (Oladiipo et. al., 2009). The resultant effect on the petroleum industries include among others, reduced or deferred production, well shut-in, pipeline replacements and/or abandonment For efficient operation of a pipeline system, steady and continuous flow without any interruption is desirable (Chang et al., 1999). The difficulties in pipeline transportation are due to this complex nature of crude oil, which cause a variety of difficulties during the production, separation, transportation and refining of oil (Al-Besharah et al., 1987).

When it comes to dealing with scale and paraffin deposition, you need a process that is:

1. PROACTIVE

2. INNOVATIVE

3. VERSATILE

Created by Calgary-based Synergetic Oil Tools Inc., Enercat uses Synergetic’s 30 years of global oil and gas service experience to do what no one has ever done before: effectively remove and prevent asphaltene and paraffin deposition, over and over again. No maintenance. No harsh chemicals. No environmental risk.

OPERATION

The innovative Enercat tool looks like a standard production tubing pup joint with a jacket in an aluminum casting. Within this jacket are quartz crystals and semi precious metals that generate a passive energy wave. Petroleum crude oil is composed of four major fractions: saturates (including waxes), aromatics, resins and asphaltenes. When crude oil flows into a wellbore, pressure and temperature are reduced. The micelle structure of the crude oil is destabilized, allowing the paraffin and asphaltene to be released into the solution, increasing oil viscosity and allowing deposition in the well tubulars.

Enercat creates a passive vibrational energy to stabilize the original micelle structure to prevent mineral and paraffin deposition and viscosity changes. This allows the solution to move smoothly and cleanly through the pipe without causing deposition problems.

APPLICATION

Enercat works in virtually any well that experiences deposition, including:

• Dual completions

• Directional

• Horizontal

• SAGD

• Water source and

• Water injection wells

Enercat works with any pumping system, with the exception of Electrical Submersible Pumps. Each application is customized for the specific well depending upon tubing size and fluid volume. Enercats will typically be run either below the pump intake or above the pump discharge, or as a tail joint at the end of the tubing string.

Easy to install, Enercat requires no external power source, maintenance or servicing and has no internal restrictions.

Enercat is, quite simply, the next level of oil well optimization: clients who switch from asphaltene and paraffin removal chemicals to Enercat save an average of $4 per barrel of processed crude.

BENEFITS

The Enercat tool is a tool to benefit from economic-wise and production-wise.

Economic Benefits

• Increases and stabilizes production rates

• Increase well ultimate recovery

• Extend Oil/Gas well life

• Reduce operational/service costs

• Reduce well downtime

• Reduces downhole chemical costs

Production Benefits

• Improved well pressure

• Cleaner flow lines

• Lower pour point and viscosity

• Increased paraffin in Solution

• Increased asphaltenes in Solution

• Reduced downhole paraffin, asphaltenes and scale

• Lower pump energy required/longer life

• Increased fluid mobility

• Reduced friction loss

• Higher API gravity of Oil

• Stabilized continuous production

• Reduced viscosity of heavy oil

• Improved well pressure